Titanium Alloys in Military Industry

Titanium alloys, with their lightweight, high strength, corrosion resistance, and high-temperature tolerance, have become indispensable materials in modern military applications. From missiles, armed helicopters, and fighter jets to warships and precision weapon systems, titanium alloys are increasingly used in military equipment.

In high-temperature, high-pressure, and corrosive environments, the stability and reliability of titanium alloys make them the preferred material for many advanced military applications. They provide strong support for military products, drive continuous advancements in defense technology, and serve as a crucial foundation for enhancing the performance and durability of modern military equipment.

As a professional supplier of titanium alloy products, Chalco's high-performance titanium alloys have been widely applied in various military equipment, delivering excellent results.

Application of titanium alloys in military aircraft

Titanium alloys, with their lightweight, corrosion resistance, and exceptional strength, are widely used in armed helicopters, fighter jets, and military transport aircraft. Titanium materials not only enhance the performance of aircraft structural components but also significantly improve maneuverability and durability, making them an indispensable key material in modern military aircraft.

Fuselage structure

The fuselage is the core structure of an aircraft, carrying passengers, cargo, and flight performance, requiring high strength and stability. The application of titanium alloys in the fuselage, with their lightweight, high strength, corrosion resistance, and fatigue resistance, can improve fuel efficiency, extend service life, and enhance safety.

Common titanium alloy grades:

- Ti-6Al-4V (TC4 / Grade 5): The most commonly used titanium alloy for military aircraft fuselage structures, offering excellent overall performance, good strength, weldability, and machinability, with relatively controllable costs.

- Ti-3Al-2.5V (TA9 / Grade 9): Excellent weldability, commonly used in welded fuselage structures, especially in areas requiring high fatigue performance and corrosion resistance.

- Ti-6Al-2Sn-4Zr-2Mo (TC11): A heat-resistant titanium alloy used in military aircraft fuselages for areas exposed to high temperatures, such as near the engine or exhaust system.

- Ti-5Al-5V-5Mo-3Cr (TB8): A high-strength, heat-resistant titanium alloy used in critical fuselage components that endure extreme stress and elevated temperatures.

- Ti-10V-2Fe-3Al (TB6): An ultra-high-strength titanium alloy used for key load-bearing joints and reinforcements in military aircraft fuselage frames to withstand concentrated loads.

Standard specifications: MIL-STD-9047, MIL-STD-9046, AMS 4911, AMS 4928

Practical application cases:

The mid-section of the F-15 fighter jet (after the third frame) uses Ti-6Al-4V titanium alloy, accounting for 20.4% of the mid-fuselage structure's weight. The rear structure (engine bay and load-bearing tail beam connecting the tail) is made entirely of titanium alloy, including bulkheads, stringers, speed brakes, and skin.

The SR-71 is an early example of extensive titanium alloy application, with almost its entire fuselage frame made of titanium alloy to withstand the high temperatures generated by hypersonic flight.

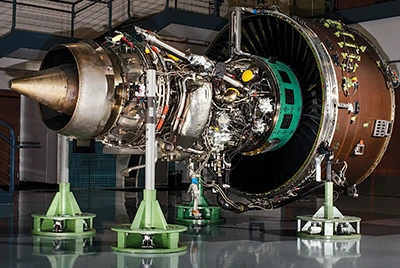

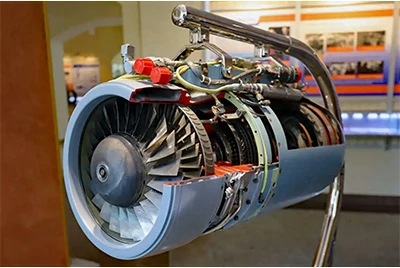

Engine parts

The engine is the power source of the aircraft, which directly affects the flight performance and safety, and needs to have high strength, high temperature resistance and reliability. Titanium alloy is very suitable for engine parts because it has excellent high temperature resistance and strength, while being light and able to withstand the high temperature and high pressure environment inside the engine.

Commonly used titanium alloy grades:

- Ti-6Al-4V (TC4 / Grade 5): Widely used, used for medium temperature compressor parts, casings, structural parts, etc.

- Ti-6Al-2Sn-4Zr-2Mo (TC11): Heat-resistant titanium alloy, used for high-pressure compressor discs, blades, casings, etc.

- Ti-5Al-5V-5Mo-3Cr (TB8): High-strength heat-resistant titanium alloy, used for high-pressure compressor discs, structural parts, etc.

- Ti-47Al-2Cr-2Nb (titanium aluminum alloy): A new generation of high-temperature lightweight alloy, used for low-pressure turbine blades, high-pressure compressor rear casings, etc.

- Ti-5Al-2.5Sn (TA7 / Grade 6): Good weldability, used for engine casings, ducts, rings, etc.

Standard specifications: AMS 4928, AMS 4983, AMS 4975, AMS 4978

Actual application cases:

The F-22 fighter F119 engine is the world's first military turbofan engine with a thrust-to-weight ratio of 10. Its high-pressure compressor blades use a large amount of heat-resistant titanium alloys such as Ti-6Al-2Sn-4Zr-2Mo (TC11) to achieve high thrust and high operating temperature.

The F-35 fighter F135 engine is currently the military turbofan engine with the largest thrust. Its compressor blades also widely use advanced titanium alloys, such as the more advanced Ti-Al-Sn-Zr-Mo-Nb alloy, to further improve performance.

Wing frame

Commonly used titanium alloy grades:

- Ti-6Al-4V (TC4 / Grade 5): The most widely used, used for major load-bearing components such as wing spars, wing ribs, wing box panels, and joints.

- Ti-3Al-2.5V (TA9 / Grade 9): Used for welding wing box structures, such as welded components of wing spars and wing ribs.

- Ti-7Al-4Mo (Ti-74): High-strength titanium alloy, used for parts such as wing roots that bear greater loads.

- Ti-10V-2Fe-3Al (TB6): Ultra-high-strength titanium alloy, used for extreme load-bearing parts such as wing-fuselage connections.

Standard specifications: MIL-T-9047, MIL-T-9046, MIL-HDBK-5

Actual use cases: F-16, F-18, Rafale fighters, etc., all use a large amount of titanium alloys in wing frame structures, especially key load-bearing components such as wing spars, wing ribs, and wing boxes. Three wing spars of the wing structure - use Ti-6Al-4V titanium alloy. Lower skin of the wing internal fuel tank - use Ti-6Al-4V titanium alloy.

Landing gear

Commonly used titanium alloy grades:

- Ti-10V-2Fe-3Al (TB6): Ultra-high strength titanium alloy, the most important titanium alloy in landing gear applications, with extremely high strength and hardenability, suitable for manufacturing the main load-bearing components of landing gear.

- Ti-6Al-4V (TC4 / Grade 5): Used for secondary load-bearing components and structural parts of landing gear, such as support structures, connectors, etc., with good comprehensive performance and relatively low cost.

- Ti-15V-3Cr-3Al-3Sn (Ti-15-3): Good cold formability, used for landing gear parts with complex shapes, such as oil pipes, actuators, etc.

Standard specification: MIL-STD-HDBK-5, MIL-STD-1530

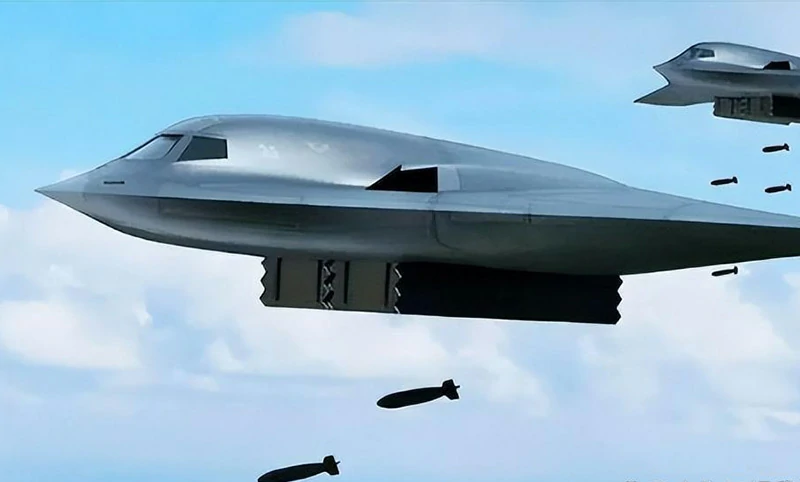

Actual application cases:

F-16 fighter landing gear: Ti-10V-2Fe-3Al (TB6) is used in key components of the F-16 fighter landing gear, such as landing gear struts and support arms

B-2 stealth bomber landing gear: In order to meet its special stealth and ultra-long-range flight requirements, the B-2 stealth bomber landing gear also uses advanced titanium alloy materials and structural designs to reduce weight and ensure strength.

Application of titanium alloy in missiles

Titanium alloys are widely used in missiles for key components such as engines, casings and control systems due to their high strength, light weight and high temperature resistance. The corrosion resistance of titanium alloys makes them reliable in extreme environments and can withstand the huge pressure and temperature changes during missile launch and flight.

Missile Body/Airframe Structure

Common titanium alloy grades: Ti-6Al-4V, Ti-3Al-2.5V, Ti-10V-2Fe-3Al, Ti-15V-3Cr-3Al-3Sn

Function: Responsible for the overall frame of the missile, bearing the aerodynamic pressure during launch and flight.

Contact us now

Missile Engine Casing/Structure

Common titanium alloy grades: Ti-6Al-4V, Ti-10V-2Fe-3Al, Ti-6Al-2Sn-4Zr-2Mo

Function: Protect missile engines and withstand high temperatures and pressures

Contact us nowMissile Nozzle/Exhaust

Common titanium alloy grades: Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo

Function: Control the ejection of gas and provide thrust.

Contact us now

Missile Control Surfaces/Fins/Wings

Common titanium alloy grades: Ti-6Al-4V, Ti-3Al-2.5V, Ti-15V-3Cr-3Al-3Sn

Function: Provide flight control and stability to help missiles maneuver.

Contact us nowApplication of titanium alloy in armored vehicles

The application of titanium alloy in armored vehicles is mainly reflected in key parts such as body shell, protective armor, chassis, suspension system and engine components. Due to its excellent strength, corrosion resistance and impact resistance, titanium alloy can effectively enhance the protection and durability of armored vehicles, while reducing the overall weight and improving mobility.

Armored vehicle body

The application of titanium alloy in armored vehicles is mainly reflected in key parts such as body shell, protective armor, chassis, suspension system and engine components. Due to its excellent strength, corrosion resistance and impact resistance, titanium alloy can effectively enhance the protection and durability of armored vehicles, while reducing the overall weight and improving mobility.

Commonly used titanium alloy grades:

- Ti-6Al-4V (TC4/5 Grade): Most commonly used in hull structures due to its good balance of strength, weldability and cost-effectiveness.

- Ti-6Al-4V ELI (23 Grade): Used in critical hull sections where higher toughness and fracture resistance are required, especially in colder environments or where enhanced ballistic performance is required.

Standard specifications: MIL-DTL-46093E, MIL-STD-9047

Armor Plate

The main function of armored vehicle armor plates is to provide effective protection against enemy fire and explosion threats. Titanium alloy, as a key material for armor plates, has the most important function of significantly reducing weight while ensuring protective performance through its high strength and lightweight characteristics, thereby improving the vehicle's mobility and response speed.

Commonly used titanium alloy grades:

- Ti-6Al-4V (TC4/5 grades): Again, a common choice for add-on armor due to its balance of performance and cost.

- Ti-6Al-4V ELI (23 grades): For armor applications that require higher ballistic performance and toughness.

- Ti-10V-2Fe-3Al (TB6): For specialized armor applications that require maximum protection, but they are more expensive and harder to manufacture.

Specifications: MIL-DTL-46093E, MIL-STD-9047

Suspension system components

The function of armored vehicle suspension components is to support the weight of the vehicle body, absorb ground impact, and ensure driving stability and comfort. The application of titanium alloy in suspension components is mainly due to its high strength and corrosion resistance, which can effectively improve the durability and performance of the suspension system and enhance the mobility and reliability of the vehicle.

Commonly used titanium alloy grades:

- Ti-5Al-2.5Sn (TA7/6 grade): good weldability and fatigue strength, suitable for springs and torsion bars.

- Ti-6Al-4V (TC4/5 grade): used for connecting rods, arms and other structural suspension parts that require high strength.

- Ti-10V-2Fe-3Al (TB6): suitable for highly stressed parts, such as heavy springs or parts in ultra-heavy vehicles.

Specifications: MIL-HDBK-5: Provides design data for titanium alloys in structural applications (including suspension systems).

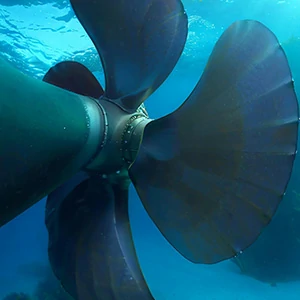

Application of titanium alloy in submarines

-

Submarine pressure hullCommon titanium alloys such as Ti-6Al-4V ELI, Ti-6Al-4V (TC4), pure titanium and PT-3V (Russian) are widely used in submarine pressure hulls. These titanium alloys provide excellent high strength, toughness and seawater corrosion resistance, and have low magnetic properties, adapting to the huge pressure of submarines in deep sea environments.

-

Ship propellers and propulsion systemsTi-6Al-4V (TC4) and Ti-Cu alloys are commonly used materials because of their high strength and fatigue resistance. They can also effectively resist corrosion and erosion from seawater, ensuring efficient operation of propellers and propulsion systems in harsh environments. In addition, titanium alloys have low noise characteristics, which helps reduce the acoustic signature of submarines or ships and enhances stealth.

-

Ship piping systems and heat exchangersPure titanium and Ti-0.3Mo-0.8Ni (TA10) alloys are often used in ship piping systems and heat exchangers. The main advantages of these materials are their excellent seawater corrosion resistance and long service life, which can effectively reduce the risk of leakage and ensure the safety and stability of ships during long-term service.

-

Sonar system components (dome, hydrophone array)Ti-6Al-4V (TC4) and pure titanium are commonly used materials for sonar system components because of their excellent acoustic properties and resistance to seawater corrosion. The use of titanium alloy in sonar domes and hydrophone arrays helps improve the underwater detection capabilities of ships and enhances their concealment and reliability.

Application of titanium alloy in military wearable equipment

Ballistic titanium helmets

Ti-6Al-4V (TC4/5 grade) and Ti-6Al-4V ELI (23 grade) are often used in the manufacture of ballistic titanium helmets due to their high strength and toughness, which can effectively resist ballistic threats. Ti-CP (commercially pure titanium) is suitable for non-ballistic critical parts, such as liner parts, to provide lightweight protection.

Contact us now

Titanium body armor plates

Ti-6Al-4V (TC4/5 grade) and Ti-6Al-4V ELI (23 grade) are commonly used in bulletproof vest plates, which have high strength, impact resistance and lightweight characteristics. β titanium alloy (such as Ti-10V-2Fe-3Al) is used for plates with higher strength requirements, providing stronger protection capabilities.

Contact us nowMilitary titanium exoskeletons

Ti-6Al-4V (TC4/Grade 5) is used for the frame structure of the exoskeleton, providing strong and lightweight support. Ti-15V-3Cr-3Al-3Sn (Ti-15-3) is suitable for complex connection structures, while Ti-3Al-2.5V (TA9/Grade 9) is used for lightweight frames and welded structures to meet the flexibility and strength required by the military.

Contact us now

Titanium military eyewear frames

Ti-3Al-2.5V (TA9/9 grade) and pure titanium (TA1, TA2) are used in the frames of military glasses and goggles, providing excellent strength and corrosion resistance while maintaining lightness and comfort.

Contact us nowApplication of titanium alloy on warships

Ship hull structure

Ti-6Al-4V (TC4/Grade 5) titanium alloy is widely used in the hull structure of warships. Due to its excellent strength-to-weight ratio and corrosion resistance, it can be used for a long time in marine environments and resist corrosion caused by salt water and other harsh environments.

Propulsion systems

Ti-6Al-4V ELI (Grade 23) titanium alloy is often used in ship propulsion system components, such as bearings, impellers, etc. Due to its excellent high temperature resistance, strength and corrosion resistance, it can work reliably in high pressure and high temperature environments.

Weapon systems

β-titanium alloys (such as Ti-10V-2Fe-3Al) are often used in shipborne weapon components. They have higher strength and toughness and are suitable for high-speed shooting and high-impact environments. Their light weight and high strength make weapon systems more efficient and reliable in combat.

Bridge structure and external components

Ti-3Al-2.5V (TA9/Grade 9) titanium alloy is used for the structure of the bridge and external devices because of its lightness, high strength and corrosion resistance, ensuring that the bridge remains stable and safe when exposed to the marine environment for a long time.

Electronic Equipment Housings

Pure titanium (TA1, TA2) is used in the shells of ship electronic equipment, providing high corrosion resistance, good electromagnetic shielding capabilities and long-term durability, protecting sensitive equipment from erosion by seawater and moisture.

Application of titanium alloy in weapons and ammunition

Gun barrels/gun tubes

Ti-6Al-4V (TC4 / Grade 5) or Ti-10V-2Fe-3Al (TB6) titanium alloys are used in the manufacture of barrels for light artillery or special firearms. Ti-6Al-4V balances strength and machinability, while Ti-10V-2Fe-3Al provides higher strength.

Breech mechanisms

The breech block mechanism for large caliber artillery or automatic weapons may be made of Ti-6Al-4V (TC4 / Grade 5) or Ti-6Al-2Sn-4Zr-2Mo (TC11) titanium alloys. Ti-6Al-4V provides strength and wear resistance, while Ti-6Al-2Sn-4Zr-2Mo enhances heat resistance.

System components

Gun recoil device components, such as hydraulic cylinders, recoil spring guide rods, or use Ti-6Al-4V (TC4 / Grade 5) or Ti-5Al-5V-5Mo-3Cr (TB8) titanium alloys.

Structural components

For special operations or individual weapon frames, receivers and other structural parts, Ti-6Al-4V (TC4 / Grade 5) or Ti-3Al-2.5V (TA9 / Grade 9) titanium alloys will be considered.

Military knives

Beta titanium alloy (such as Ti-10V-2Fe-3Al) is used in military knives and blades, providing extremely high hardness and wear resistance, ensuring that the knives remain sharp under extreme conditions and adapt to high-intensity use. Its lightweight properties also make it more convenient to carry.

Titanium alloys are widely used in firearms and weapons. The following are some practical application cases:

M28 120mm crockett recoil gun parts: The barrel, charge chamber, nozzle, firing piston and other parts of the M28 120mm Crockett recoil gun are forged with Ti-6Al-6V-2Sn-0.5Fe-0.5Cu alloy. This (α+β) alloy provides excellent strength and toughness, reducing the weight of the entire gun by 34.9%, from 104.4kg to 68kg, while maintaining high power and mobility.

T66 76mm artillery parts: Since the 1970s, Ti-6Al-4V-2Sn alloy has been used to manufacture gun barrels, while Ti-6Al-4V, Ti-7Al-4Mo, Ti-5Al-1.5Fe-1.4Cr-1.2Mo alloys have been used for parts such as chambers, nozzles and firing pistons. These titanium alloys reduce the weight of the artillery. The tail frame and gun mount of the T66 76mm artillery are 93.55kg lighter than steel after using titanium alloy, which improves the mobility of the artillery.

T227 81mm mortar parts: The base plate and plug of the T227 81mm mortar are made of titanium alloy. After the base plate uses industrial pure titanium, it weighs only 10.9kg, which is 50% lighter than the steel plate. This design reduces the weight of the gun, increases the range (from 3600 meters to 4500 meters), and improves the mobility of the artillery.

Japanese 155mm mortar parts: Japan's 155mm mortar uses Kobe Steel's Ti-6Al-4V alloy plate with a thickness of 5mm and 8mm. After welding, the weight of the gun body is reduced by 50%. This technology provides strength and durability while reducing the weight of the weapon and ensuring combat reliability.

Japanese 100mm mortar base plate: The base plate of the Japanese 100mm mortar uses TA7 alloy, which is 10kg lighter than the steel base plate, improving mobility and combat efficiency. The design was put into serial production in 1983, improving the performance of the mortar and reducing its weight.

82mm mortar parts: The 82mm mortar equipped in 1984 uses a titanium alloy for the barrel, base and bracket, which is 16.6kg lighter than the steel base plate. The application of titanium alloy improves the mobility of the mortar and effectively reduces its weight, improving its overall combat effectiveness.

M777 howitzer parts: The M777 howitzer is made of titanium alloy, which reduces its weight by about 50%, and is 3,150 kg lighter than the old M198 artillery. The use of titanium alloy does not affect its range and accuracy, but significantly improves its mobility, making the system more suitable for rapid deployment and combat.

What services can Chalco provide for you?

As a world-leading supplier and manufacturer of titanium alloys, Chalco, with its many years of experience in the field of titanium alloys, is able to provide first-class products and comprehensive technical support for the military industry. If you have any titanium product needs, please contact us in time.Quick Quote

High-quality titanium alloy material supply

Chalco provides a variety of high-performance titanium alloy materials, including Ti-6Al-4V, Ti-6Al-6V-2Sn, etc., which are suitable for key equipment such as warships, artillery, missiles, etc. Our titanium alloy materials meet international standards and ensure long-term stable operation in harsh environments.

Customized production

According to customer needs, Chalco can provide customized titanium alloy products to meet specific size, shape, alloy composition and performance requirements. This includes titanium alloy plates, bars, tubes, forgings and other products.

Surface treatment

Chalco also provides titanium alloy surface treatment services, such as anodizing and coating, to improve the corrosion resistance and wear resistance of titanium alloys and adapt to extreme working environments.

Processing and manufacturing

Chalco provides titanium alloy processing services, including cutting, milling, welding, drilling, etc., to ensure that titanium alloy products meet military standards and specific application requirements.

Quality control and testing

Chalco conducts strict quality inspections on each batch of titanium alloy materials to ensure that they meet international standards, and provides material test reports and compliance certification.

Technical Support and Consulting

Chalco provides technical support to customers to help solve technical problems in titanium alloy applications, and provides professional material selection and design optimization suggestions according to needs.