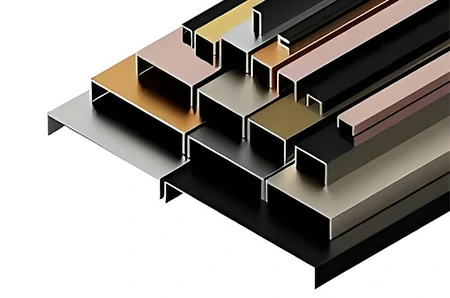

Titanium Profile

Titanium profiles are extruded parts of various cross-sections produced by extrusion of titanium alloy or pure titanium, and are widely used in aerospace, chemical, medical, marine and other fields.

Titanium profiles are usually divided into standard titanium profiles and special titanium profiles. Chalco can provide standard titanium profiles of various sizes and customized titanium profiles of various special cross-sections.

Standard titanium profiles

Titanium Bar

Diameter: 0.125” – 8”

Length: 6m or customized

Shape: Titanium round bar, titanium rectangular bar, titanium square bar, titanium flat bar, titanium hexagonal bar

Specification: ASTM B348, ASME SB-348, ASTM F67

Application: Aircraft engine parts, artificial joints, golf clubs, tennis rackets and bicycle frames

Surface treatment: pickling, anodizing, polishing, painting.

Popular titanium bars:

- Grade 2 titanium bar

- Grade 2 titanium bar

- 6AL-4V titanium bar

- 6AL-4V ELI titanium bar

- Ti-5Al-2.5Sn bar

- Ti-6Al-6V-2Sn bar

Titanium tube

Diameter: 0.25” – 4”

Length: 6m or customized

Shape: titanium round tube, titanium rectangular tube, titanium square tube, titanium flat tube, titanium hexagonal tube

Specification: ASTM B338, AMS4941, AMS-4943

Application: aircraft fuel system, hydraulic system, fluid pipelines in chemical plants, bicycle tripods, fishing rods

Surface treatment: anodizing, polishing, painting.

Popular titanium tube:

- Grade 2 titanium tube

- Grade 4 titanium tubes

- 6Al-4v titanium tube

- Ti-3Al-2.5V tube

- Ti-6Al-4V ELI tube

- Grade 7 titanium tube

Titanium angle

Titanium angle is a structural profile made of titanium, usually with an L-shaped cross-section, known for its high strength, light weight and excellent corrosion resistance.

Contact us now

Alloy: Grade 4, 6Al-4v

Type: Equal-sided Titanium angle, Unequal-sided Titanium angle

Side width range: 25-180mm

Thickness range: 0.5-80mm

Length customization: Supports 6-12m standard length, special requirements can be customized

Common sizes of equilateral Titanium angle: 30x30mm, 40x40mm, 50x50mm, 65x65mm, 75x75mm, 80x80mm, 100x100mm

Common sizes of unequal-sided Titanium angle: 2" x 1-1/2", 2-1/2" x 2", 3" x 2", 3-1/2" x 2-1/2", 4" x 3", 5" x 3", 6" x 4"

Common applications: aircraft frames and components, building structure frames, ship structures

Titanium I-Beam

Titanium I-beam is a structural beam made of titanium with an I-shaped cross-section. It has high strength, light weight and excellent corrosion resistance and is widely used in demanding industries.

Contact us now

Common alloys: Ti-6Al-4V, Gr1, Gr2, Ti-3Al-2.5V

Height (web height): usually 50-300mm, special customization can reach 500mm.

Flange width and thickness: flange width range 20-150mm, thickness 5-30mm, adjusted according to load-bearing requirements.

Standard length: 6-12m, support non-standard customized cutting.

Application: wing frame, offshore platform structure, building structural frame, vehicle frame..

Titanium t beam

Titanium t beam is a titanium structural profile with a T-shaped cross-section, which is widely used due to its light weight, high strength and corrosion resistance.

Contact us now

Thickness:0.125”-1”

Height:0.75”-4”

Width: :0.75”-4”

Length: 12m or customized

Application: Building support frames, aircraft structure support, medical equipment support frames

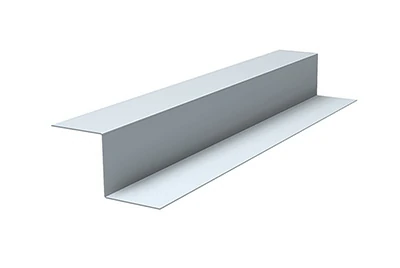

Titanium z section

Titanium Z-section is a titanium structural profile with a Z-shaped cross-section, usually used to support structural parts.

Contact us now

Common alloys: Gr2,6al-4v, Ti-3Al-2.5V, Ti-6Al-4V ELI

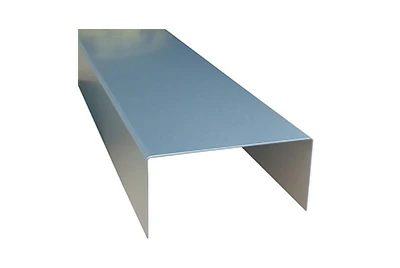

Titanium u channel

Titanium U-shaped channel is a titanium profile with a U-shaped cross section. It is used as a support or guide profile and is more commonly used in environments that require corrosion resistance and high temperature resistance.

Contact us now

Common alloys: Grade 2, Grade 5 and Grade 9

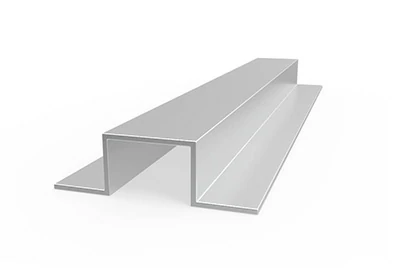

Titanium top hat section

Titanium top hat profile is a titanium profile with a "top hat" cross section. Due to its unique design, it can provide good bending and twisting resistance while maintaining high strength and light weight.

Contact us now

Common alloys: Grade 2, 6Al-4v

Special titanium profiles

Special aluminum profiles have relatively complex shapes and usually need to be customized. They are mainly used in aerospace, construction and furniture industries, automotive industry and transportation industry.

Aerospace titanium profiles

Titanium extrusions are widely used in aircraft fuselage and wing structures, such as fuselage frames, wing beams and skin frames, to improve load-bearing capacity and reduce weight.

In power and hydraulic systems, titanium alloy pipes and engine compartment components enhance high pressure and high temperature resistance; in addition, titanium extrusions are also used in landing gear auxiliary structures and cabin window frames, balancing lightweight and impact resistance requirements, and improving aircraft safety and durability.

Titanium alloy hydraulic pipeline

Titanium alloy landing gear outer tube

Titanium alloy engine blades

Titanium alloy profiles for automobiles

Titanium alloy profiles are widely used in automobiles to improve performance and durability. Titanium profiles are mainly used in exhaust systems (such as exhaust pipes, mufflers, turbocharger components), structural parts and frames (such as chassis longitudinal beams, cross beams, suspension system components) and fasteners and connectors (such as wheel hub bolts and high-strength screws).

Titanium alloy suspension

Titanium alloy exhaust pipe

Titanium alloy anti-collision beam

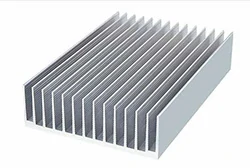

Titanium radiator profiles

Titanium radiator profiles are heat dissipation materials designed using the corrosion resistance and high strength characteristics of titanium alloys, and are often used in thermal management applications in high-temperature, highly corrosive environments. Although titanium has poor thermal conductivity, its excellent corrosion resistance and high-temperature performance make it an ideal choice in some special fields.

Titanium alloy radiator display:

Titanium alloy door and window profiles

Titanium alloy door and window profiles are door and window frames made of titanium alloy materials, which have excellent corrosion resistance, strength and oxidation resistance. They are usually used in high-end buildings and special environments, providing longer service life and higher safety.

Titanium alloy doors and windows display:

Titanium alloy cabinet profile

Titanium alloy cabinet profiles are profiles designed for cabinet frames and structures based on titanium alloys, which have extremely strong corrosion resistance and oxidation resistance. They not only enhance the durability of the cabinets, but also provide a modern and stylish appearance for the kitchen environment.

Titanium profiles for construction

Titanium extrusions are widely used in buildings, mainly for load-bearing frames and beams, such as bridge beams and connectors, to improve structural stability and extend service life.

In building wrapping and decoration systems, titanium alloy profiles are used for roofs, curtain wall support frames and decorative components, combining lightweight, earthquake resistance and aesthetic effects; in addition, titanium extrusions also perform well in special environments, such as marine buildings and buildings in highly polluted industrial areas, with excellent corrosion resistance and long life.

Titanium profiles for chemical industry

Titanium extrusions are used in the chemical industry in oil extraction and refining equipment. Titanium alloy drill pipes improve operating efficiency and reduce the risk of breakage, and titanium hydraulic pipes extend their service life in sulfur-containing gas fields; in refining equipment, titanium extruded pipes are resistant to high temperatures and corrosion, and titanium alloy plates are used for reactor linings to prevent equipment corrosion and leakage.

Medical titanium profiles

Titanium alloy extrusion profiles are widely used in the medical field, including artificial joints, spinal fixation systems, dental implants, orthodontic instruments, high-precision surgical tools and implantable medical device components.

Titanium alloys (such as Ti-6Al-4V, Ti-5 grade alloys, etc.) can improve the service life of implants, promote bone healing, reduce stress shielding effects, and effectively avoid postoperative complications due to their excellent mechanical properties, biocompatibility and corrosion resistance.

What are the advantages of Chalco titanium profiles?

Extreme deformation capability

The titanium extrusion method uses a three-dimensional compressive stress state, which can achieve large plastic deformation at one time, and is particularly suitable for the processing of low-plasticity and difficult-to-deform materials.

Complex section forming

It can produce pipes and profiles with special-shaped holes, variable thickness and other features. The forming capacity covers the manufacturing of 0.5mm thin-walled tubes to multi-cavity complex sections, and the geometric complexity far exceeds the limit of rolling process.

Precision dimensional control

The surface roughness can reach Ra0.8μm, the wall thickness tolerance is controlled within ±0.05mm, and the finished product straightness error is less than 1/1000, which is better than the traditional rolling process.

Optimization of organizational uniformity

The severe shear deformation generated by the extrusion process promotes grain refinement, and the uniformity of the product microstructure is improved by more than 40% compared with castings.

What surface finishes are available for Chalco titanium extrusions?

Sandblasting

White corundum particles are used to roughen the surface, remove the oxide layer, and enhance coating adhesion. The surface roughness achieved is Ra1.6-3.2μm, with a single treatment time of 15-30 seconds.

Pickling process

A mixed acid solution of HF and HNO₃ is used to remove the surface reaction layer while minimizing hydrogen absorption to less than 0.001%. The treatment is conducted at 20-25℃ for 3-5 minutes.

Anodizing

An electrolyte is used to generate a 5-20μm oxide film, improving corrosion resistance and enabling a variety of color effects. Typical process parameters include a voltage of 20-100V and a current density of 0.5-2A/dm².

Micro-arc oxidation

This process forms a 50-200μm ceramic layer, significantly increasing hardness (HV1500-2000) and reducing the friction coefficient. It is particularly suitable for surface treatment in high-temperature conditions above 500℃.

Mirror polishing

Mechanical grinding and chemical polishing techniques create an ultra-smooth surface with a roughness of Ra0.05μm. The polishing speed ranges from 900 to 1800m/min, ensuring a flatness error of ≤0.01mm/m.

Chemical etching

Using photomask technology, micron-level pattern etching is achieved with an accuracy of ±5μm, making it suitable for anti-counterfeiting markings.

Anti-adhesion coating

Graphite emulsion or molybdenum disulfide coatings are applied to reduce the friction coefficient to 0.08-0.12, making them ideal for sliding components.

Biocompatibility treatment

Vacuum annealing combined with passivation forms a dense oxide layer that meets medical device standards.

Metal composite plating

Copper, nickel, or chromium electroplated coatings with a thickness of 10-50μm enhance conductivity and electromagnetic shielding. The bonding strength exceeds 50MPa.

Laser surface alloying

A fiber laser is used to melt and coat a WC-Co hard layer on the surface, improving wear resistance by 8-10 times.

What services can Chalco provide?

Customized processing service: Customized sizes and shapes of titanium extrusions are provided according to customer needs to meet special application requirements.

Multiple surface treatment options: A range of surface treatment options are provided, including sandblasting, pickling, anodizing, micro-arc oxidation, mirror polishing, chemical etching, etc., to enhance the functionality and aesthetics of titanium extrusions.

Technical consultation and support: Professional technical consultation is provided to help customers choose titanium alloy materials and surface treatment methods suitable for their applications.

Quality control and testing: Strict quality control system ensures that each batch of titanium extrusions meets international standards and customer requirements. Component analysis, hardness testing, surface quality inspection and other testing services can be provided. Quality inspection books are provided to ensure that the products meet the customer's technical requirements and quality standards.

After-sales service: Provide comprehensive after-sales service to solve problems that customers may encounter during use and ensure that customers use worry-free.

Free samples: Free samples are provided for customers to test and verify to ensure that titanium extrusions meet the expected performance standards.

Bulk price discounts: For bulk orders, Chalco can provide price discounts to help customers save costs when purchasing.