Gr5/ Ti-6Al-4V Titanium Tube Supply

Grade 5 Titanium Alloy (Ti-6Al-4V) is a high strength, low density titanium alloy with excellent mechanical properties and corrosion resistance for use in harsh environments. It can be optimized by heat treatment.

Grade 5 titanium tube inherits the characteristics of Grade 5 titanium alloy, with high strength, corrosion resistance and good weldability. It is widely used in aviation, chemical, medical and other industries, and is particularly suitable for occasions that need to withstand high temperatures and extreme conditions.

Gr5/ Ti-6Al-4V titanium tube product overview

Equivalent names: Titanium Grade 5; WERKSTOFF NR. 3.7165; UNS R56400

Diameter: 0.500" (12.7 mm) to 4.000" (101.6 mm)

Length increments: 1', 3', 5' and 20'

Dimensions: Available in S10, S40 and S80 dimensions.

End: Plain End, Beveled End, Treaded

Additional services: custom design and processing; precision cutting; welding; bending; forming; surface treatment optimization

Surface treatment: polishing; electrolytic polishing; pickling; anodizing; anti-corrosion coating; section treatment; passivation

Specification: ASTMF1472, ASTM B861, ASTM B338 / ASME SB338 and other customer required specifications.

Note: The product performance and specifications we introduce are based on ASTM standards, but can also be customized according to other standards. Welcome to consult according to your needs.

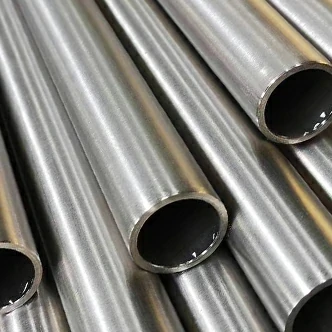

Chalco Gr5/ Ti-6Al-4V titanium tube product display

-

Gr5/ Ti-6Al-4V seamless pipe

Made of high-strength Grade 5 titanium alloy, it has excellent mechanical properties and corrosion resistance and is widely used in the aviation, medical and chemical industries.

-

Gr5/ Ti-6Al-4V drawn tube

Processed through a drawing process, Gr5 drawn titanium tubes have more precise dimensions and better surface quality, making them suitable for applications requiring high strength and light weight.

-

Gr5/ Ti-6Al-4V welded pipe

Manufactured using a welding process, Gr5 welded titanium pipes are suitable for a variety of industrial environments, with excellent strength and corrosion resistance.

-

Gr5/ Ti-6Al-4V ERW pipe

It adopts resistance welding technology, provides high production efficiency and good welding quality, and is often used in applications with lower pressure.

-

Gr5/ Ti-6Al-4V hydraulic pipe

Designed specifically for hydraulic systems, Gr5 titanium hydraulic tubes feature high strength, corrosion resistance, and are suitable for demanding hydraulic environments.

-

Gr5/ Ti-6Al-4V high pressure pipe

Titanium tubes used in high-pressure environments have good strength and high-pressure resistance and are widely used in aviation, chemical and other fields.

-

Gr5/ Ti-6Al-4V Fabricated Tube

After welding, bending, cutting, flaring and other processes, it is suitable for applications that require higher precision and special shapes, such as medical equipment and high-performance engineering.

-

Gr5/ Ti-6Al-4V electrolytic polishing tube

Through the electrolytic polishing process, it has a smooth surface and better corrosion resistance, and is widely used in industries requiring high hygiene standards such as food and medical.

Chalco Gr5/ Ti-6Al-4V titanium tube chemical composition

| Element | Min | Max |

|---|---|---|

| Al | 5.5 | 6.75 |

| C | - | 0.08 |

| Fe | - | 0.4 |

| H | - | 0.015 |

| N | - | 0.05 |

| Ti | Balance | |

| O | - | 0.2 |

| V | 3.5 | 4.5 |

Chalco Gr5/ Ti-6Al-4V titanium tube physical properties (room temperature)

| Specific Heat (0-100°C) | 565 | J.kg-1.°K-1 |

|---|---|---|

| Thermal Conductivity | 6.7 | W.m -1.°K-1 |

| Thermal Expansion | 8.6 | μm/μm/°C |

| Modulus Elasticity | 120 | GPa |

| Electrical Resistivity | 17.1 | Ohm-cm |

| Density | 4.43 | g/cm3 |

Chalco Gr5/ Ti-6Al-4V titanium tube mechanical properties

| Temper | Annealed | Cold-worked | ||

|---|---|---|---|---|

| Tensile Rm | 116 | ksi (min) | 150 | ksi (min) |

| Tensile Rm | 800 | MPa (min) | 1034 | MPa (min) |

| R.p. 0.2% Yield | 102 | ksi (min) | 135 | ksi (min) |

| R.p. 0.2% Yield | 700 | MPa (min) | 930 | MPa (min) |

| Elongation (2” or 4D gl) | 10 | % (min) | 8 | % (min) |

Chalco Gr5/ Ti-6Al-4V titanium tube service and quality assurance

Chalco Titanium offers a wide range of high-quality titanium products and custom solutions to ensure your needs are met. Whether it is standard sizes or custom specifications, we are committed to providing you with a convenient and professional shopping experience, ensuring efficient and satisfactory service.

- Diverse Sizes and Types: Gr5 Titanium Tubes are available in a variety of sizes and types starting from 3.0mm, including drawn, seamless rolled and longitudinally welded tubes.

- Stock and Custom Options: Titanium tubes of common sizes can be obtained directly from stock, and can also be customized according to customer specifications.

- Long-term supply agreements: We provide framework agreements for customers with long-term supply needs, ensuring stable prices and quantities over the agreed period.

- Product Testing: To ensure that no inferior products are produced and shipped, Chalco titanium tubes undergo a series of rigorous tests, including material identification test, hardness test, mechanical property test, chemical composition test, intergranular corrosion test, flattening/flaring test, etc.

- Quality Assurance: Factory tested and certified according to EN 10204/3.1B. Other certifications available including third party test reports and 100% radiographic inspection reports.

- Certificates provided: A variety of documents are provided, including fumigation certificates, heat treatment charts, quality assurance plans (QAP), packing lists, raw material test reports, material traceability reports, certificates of origin, commercial invoices, etc.

- Packaging and transportation: Titanium alloy Gr5 pipes are packed in standard packaging or customized according to customer needs. They are usually packed in environmentally friendly plastic bags and placed in wooden pallets or wooden boxes for transportation to ensure that the product quality is not damaged.

Chalco Gr5/ Ti-6Al-4V titanium tube product advantages

Gr5/ Ti-6Al-4V is the most commonly used alloy. Its strength is significantly higher than commercially pure titanium (grades 1-4) while having the same stiffness and thermal properties (excluding thermal conductivity, which is about 60% lower for grade 5 than CP titanium). It has many advantages, one of which is that it is heat treatable. This grade is an excellent combination of strength, corrosion resistance, weldability and machinability.

- High Strength Titanium Alloy

- Heat treatable

- Good ductility

- Good processability

- Good weldability

Chalco Gr5/ Ti-6Al-4V titanium tube product cooperation areas

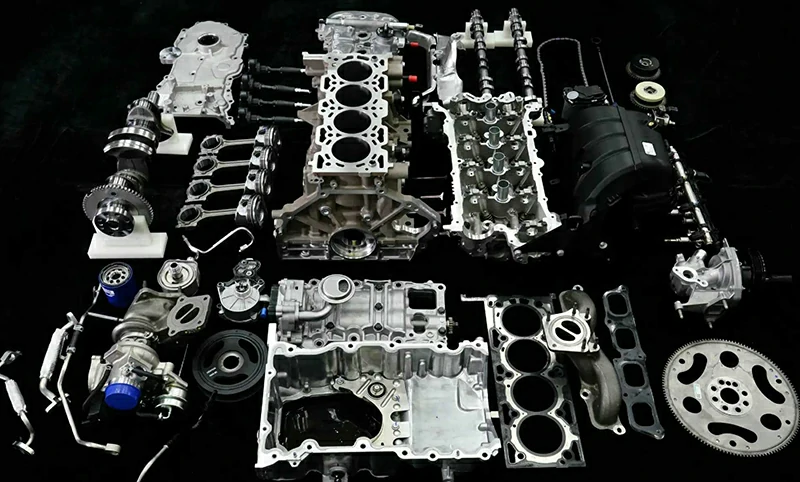

- Racing car parts

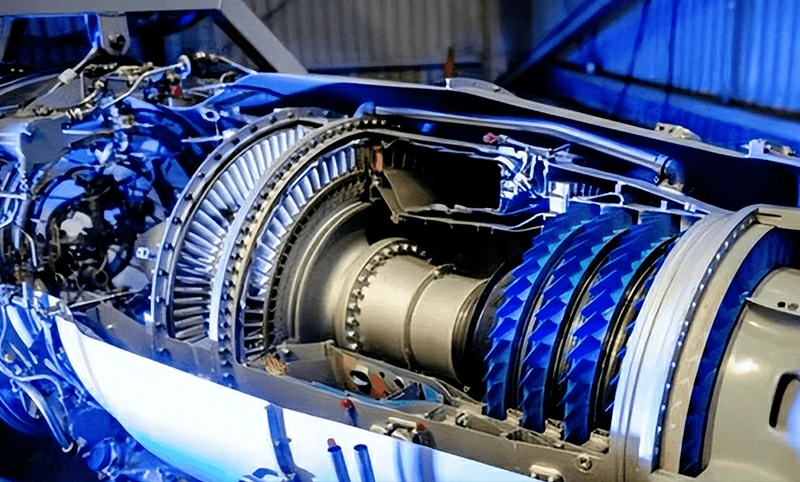

- Aircraft engine parts

- Air body parts

- Offshore oil and gas equipment

Chalco Gr5/ Ti-6Al-4V titanium tube stock size reference

| Stock Wall thickness of Gr5/ Ti-6Al-4V titanium tube | |||

|---|---|---|---|

| Types of Gr5/ Ti-6Al-4V Titanium Tube | Out diameter (OD) | Wall thickness | Length |

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Up to 6 Meters |

| Grade 5 Titanium Seamless Tube (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Up to 6 Meters |

| Grade 5 Titanium Welded Tube (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Up to 6 Meters |

| Gr5/ Ti-6Al-4V titanium round tube sizes | |

|---|---|

| Wall Thickness | Titanium Tube Sizes (O.D.) |

| .010 | 1/16”, 1/8”, 3/16" |

| .020 | 1/16”, 1/8”, 3/16”, 1/4”, 5/16”, 3/8" |

| .012 | 1/8" |

| .016 | 1/8”, 3/16" |

| .028 | 1/8”, 3/16”, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1 1/2”, 2" |

| .035 | 1/8”, 3/16”, 1/4”, 5/16", 3/8", 7/16", 1/2", 16", 5/8", 3/4", 7/8", 1", 1 1/4", 1 1/2", 1 5/8", 2", 2 1/4" |

| .049 | 3/16", 1/4", 5/16", 3/8", 1/2", 16", 5/8", 3/4", 7/8", 1", 1 1/8", 1 1/4", 1 1/2", 1 5/8", 2", 2 1/4" |

| .065 | 1/4", 5/16", 3/8", 1/2", 16", 5/8", 3/4", 7/8", 1", 1 1/4", 1 1/2", 1 5/8", 1 3/4", 2", 2 1/2", 3" |

| .083 | 1/4", 3/8", 1/2", 5/8", 3/4", 7/8", 1", 1 1/4", 1 1/2", 1 5/8", 1 7/8", 2", 2 1/2",3" |

| .095 | 1/2", 5/8", 1", 1 1/4", 1 1/2", 2" |

| .109 | 1/2", 3/4", 1", 1 1/4", 1 1/2", 2" |

| .120 | 1/2", 5/8", 3/4", 7/8", 1", 1 1/4", 1 1/2", 2", 2 1/4", 2 1/2", 3" |

| .125 | 3/4", 1", 1 1/4", 1 1/2", 2", 3", 3 1/4" |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

| Gr5/ Ti-6Al-4V titanium square pipe schedule list | |

| 1/8" IPS (.405"O. D.) | 3 1/2" IPS (4.000"O. D.) |

| SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/4" IPS (.540"O. D.) | 4" IPS (4.500"O. D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 3/8" IPS (.675"O. D.) | 5" IPS (5.563"O. D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/2" IPS (.840"O. D.) | 6" IPS (6.625"O. D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 3/4" IPS (1.050"O. D.) | 8” IPS (8.625"O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 1" IPS:(1.315′O. D.) | 10" IPS (10.750"O. D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

| 1-1/4" IPS (1.660"O. D.) | 12" IPS (12.750"O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

| 1-1/2" IPS (1.900"O. D.) | 14" IPS (14.000"O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

| 2" IPS (2.375"O. D.) | 16" IPS (16.000"O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

| 2 1/2" IPS (2.875"O. D.) | 18" IPS (18.000"O. D.) |

| SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

| 3" IPS (3.500"OD) | |

| SCH 5, 10, 40, 80, 160, XXH | |

Frequently asked questions about Gr5/ Ti-6Al-4V titanium tube purchase

1. How to choose a suitable titanium tube supplier?

When choosing the right supplier, you need to consider the following:

- Quality Assurance: Ensure that the products provided by suppliers meet international standards and have strict quality testing processes.

- Delivery capability: Choose suppliers who can deliver on time and support customized requirements.

- Service support: whether the supplier provides professional pre-sales, sales and after-sales services.

- Experience and Reputation: Choosing suppliers with many years of industry experience and a good reputation can ensure a stable product supply and long-term cooperative relationship.

In these aspects, Chalco Titanium provides high-quality Gr5/Ti-6Al-4V titanium tubes and customized services with its many years of experience in titanium alloy production. We strictly produce in accordance with international standards and have a complete testing system to ensure that each titanium tube meets industry requirements. Whether it is a standard product or a special customization, we can provide efficient, reliable delivery and support.

2. What are the main application areas of Gr5/Ti-6Al-4V titanium tube?

Gr5/Ti-6Al-4V titanium tubes are mainly used in aerospace, chemical equipment, medical equipment, marine engineering and high-pressure hydraulic systems, and are particularly suitable for environments that require high strength, light weight and excellent corrosion resistance.

3. What specifications and sizes are available for Gr5/Ti-6Al-4V titanium tubes?

Gr5/Ti-6Al-4V titanium tubes are available in a variety of sizes and specifications, including seamless tubes, drawn tubes, welded tubes, etc. We can provide customized services according to customer needs to ensure that specific project requirements are met.

4. How to ensure the quality of Gr5/Ti-6Al-4V titanium tube?

All titanium tubes undergo rigorous quality testing, including chemical composition analysis, hardness testing, surface defect inspection, wall thickness and dimensional accuracy testing, etc., to ensure that each titanium tube meets international quality standards.

5. How long is the delivery time for Gr5/Ti-6Al-4V titanium tube?

The delivery time depends on the required specifications and quantity. Titanium tubes of common specifications can generally be delivered within 1-2 weeks. For customized products, we will confirm the delivery time with the customer to ensure on-time delivery.

6. How to choose the appropriate type of Gr5/Ti-6Al-4V titanium tube?

The type of titanium tube you choose depends on the specific application requirements. For example, for applications that require high pressure or liquid transmission, you can choose hydraulic tubes or high-pressure tubes; for applications that require complex shapes, you can choose Fabricated titanium tubes.

7. Can Gr5/Ti-6Al-4V titanium tubes be customized?

Yes, we can provide customized services according to customer needs, including different lengths, outer diameters, wall thicknesses, welding methods, etc. to ensure that customer-specific technical requirements are met.

8. What is the price of Gr5/Ti-6Al-4V titanium tube?

The price of titanium tubes is affected by many factors, including size, type, processing technology and quantity. We offer competitive prices and can provide customized quotes based on your needs.

9. How to package and transport Gr5/Ti-6Al-4V titanium tubes?

We use environmentally friendly materials for packaging, usually plastic bags and then put them in wooden pallets or wooden boxes to ensure that the products will not be damaged during transportation. The mode of transportation is selected according to customer needs, supporting sea transportation, air transportation and other modes.